When the sample is relatively robust, i.e. hard and strongly adhering, this allows imaging without tip-induced deformation in a broad range of tip-sample interaction forces. One may choose using both soft AFM cantilevers to obtain true surface topography and stiff AFM cantilevers to ensure high topographic and phase contrast.

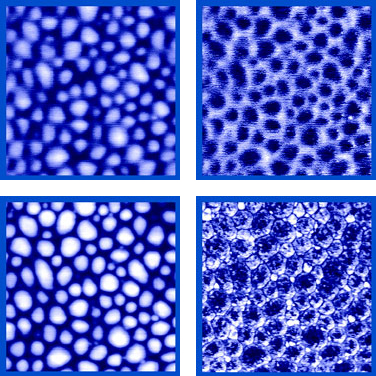

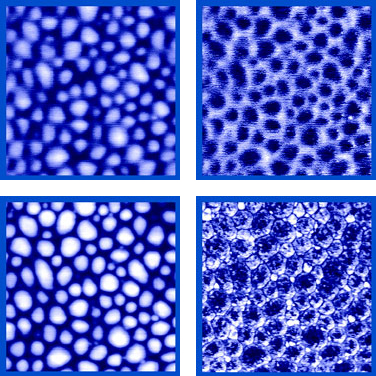

| Fig. 1. SEBS60 block-copolymer sample with a cryomicrotomed surface was imaged by Tapping Mode AFM under light (top) and hard (bottom) tapping conditions. The light tapping provide true topography (left), while hard tapping allows better material contrast in phase images (right). Image courtesy of Dr. Sergei Magonov (Digital Instruments / Veeco Metrology Group). |

|

The harder the surface, the wider the choice of AFM techniques that can be used for its investigation. The contact mode technique is still the speediest and roughest among them.

When in tapping mode, "hard" tapping conditions are usually used to obtain good material sensitive contrast in phase imaging, while "light" tapping keeps the maximum of the topography data (see Fig. 1). "Light" tapping conditions imply lower free amplitudes and higher setpoint values.

Contact mode

Long AFM cantilevers having relatively low spring constant below are usually used in contact mode. The choice between standard contact mode AFM probes HQ:CSC17/Al BS and DLC coated contact mode AFM probesHQ:CSC17/HARD/Al BS depends on the resolution needed.

When in liquid, one can use AFM probes without back side coating (HQ:CSC17/No Al) or AFM probes with a chemically inert Cr-Au coating (HQ:CSC17/Cr-Au BS or HQ:CSC17/Cr-Au).

Tapping mode

The tip-sample interaction force depends on the adhesive properties of material, the sharpness of the AFM probe tip and the scanning mode. If the experimental conditions permit, one should avoid using stiff AFM cantilevers that may cause severe deformation and even damaging of the sample. Softer AFM cantilevers usually show better and more reproducible results. However, in some experiments, e.g. very hard and/or sticky samples, stiff AFM cantilevers are required. For unknown physical properties of the domains it is recommended using AFM probes of the HQ:NSC14 series that feature an intermediate spring constant of ~5N/m.

Sharper AFM tips provide higher lateral resolution. This advantage should be balanced against the scanning speed.

For imaging in liquids, the choice of the AFM probe is usually limited to those having resonance frequency of 50-70kHz in air (HQ:NSC18). It is generally recommended to use uncoated AFM cantilevers in liquids or AFM probes with l chemically stable Cr-Au coating.

Non-contact mode

AFM cantilevers having high spring constant of 20-100N/m and the highest possible resonance frequency are usually used in non-contact mode.