Characterization of Mechanical Properties

Measuring topography and friction

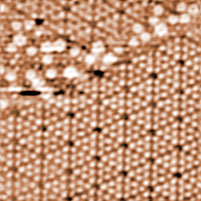

Viewing topography by itself is very informative in the studies of in-situ crystal growth [118, 826], monitoring deformations in various materials [149, 208, 658, 930, 1225] and especially in viewing ordering of structural units at nanoscale [7, 58, 59, 61, 518, 721, 777 812, 1350] (browse also thematic reference lists in the Reference collections section). Of these, surface reconstruction phenomenon is studied very well because observation of atomically resolved surfaces of silicon become in a way a benchmark for SPM apparatus as well as for quality of a scanning AFM tip (Fig. 1). In the past two decades significant progress has been achieved in improvement of SPM resolution and surface reconstruction of many substances was resolved at nanoscale. The most commonly used SPM methods to resolve atomic structures are Scanning Tunneling Microscopy for investigations of conductive materials and Non-Contact AFM (NC-AFM) for both conductive and nonconductive materials which exploit the shift in resonant frequency of an AFM cantilever as a measure of tip-surface interactions.

Fig. 1 AFM image of Si(111) 7x7 surface reconstruction taken by JEOL JSPM-4500A microscope in tapping mode. Scan size 4x4nm, height 0.4nm.

Topographical and frictional (tribological) investigations by means of Scanning Force Microscopy allows for measuring various geometries on the sample surfaces, as well as a number of related parameters such as surface roughness (as a rule, root-mean-square or RMS-roughness is considered), homogeneity etc. Also, such measurements can provide indirect information on mechanical properties of the surfaces or their fragments such as wear resistance, elasticity (stiffness) and so on [593, 1035]. Atomic Force Microscopy for surface topography measurements and Lateral Force Microscopy [1308] are often used in a couple yielding more fruitful, reliable and correct results.

Scanning Tunneling and Scanning Force Microscopy are very attractive techniques for the characterization of nanostructures prepared by various methods. Augustin et al. [891] investigate the shape and appearance of quite different nanostructures: regular gold particles deposited through the latex particles on glass; tube-like tracks in mica with aspect ratio of 105, made by heavy ion irradiation; atomic-scale modifications made by STM tip on TaNi2Te2 atomically flat surface and on blue bronze Rb0,3MoO3. Analysis of scanned images can provide insight to the formation mechanisms of such nanostructures and help to vary technological process to attain the desired result.

Scanning Probe Microscopy is a method of choice for studying of sputtered and evaporated thin films. These films, as a rule, are amorphous or polycrystalline and their structure are found to be predominantly columnar. Many thin film properties are affected by this columnar microstructure. These are thin optical coatings such as MgF2 and LaF3 [387, 688, 1209], a number of various metal films deposited using systems from different suppliers [765]. AFM helps to verify and extend the so-called Structure Zone Model describing the effect of deposition conditions on the columnar microstructure of thin films.

Surface roughness is an important factor that influences optical scattering. Reducing surface roughness is a major means for improvement of optical systems performance. Ion-beam sputtering deposition (IBSD) is shown to be an excellent method for making low scattering coatings. Lee et al. [626] use Atomic Force Microscopy to determine the quality of dual beam ion sputtered (DBSD) TiO2 films for optical applications in order to reveal the influence of various sputtering parameters such as deposition energy and oxygen concentration. Authors find conditions result in the best smoothness and minimal surface roughness of the final films.

Characterization of the particle size, shape and surface morphology is critical for quality control and assurance of the physicochemical properties of final products such as pharmaceutical solid particles including powders and granules. Surface roughness is known to play an important role in the manufacturing process and to affect the physicochemical properties of the drug products. Li and Park [505] perform fractal analysis of pharmaceutical particles by Atomic Force Microscopy. Characterization of surface roughness involves two steps: instrumental measurement and quantification of the surface roughness. The latter includes two attributes: roughness heights and lateral dimensions. Commonly used parameters such as arithmetic mean surface roughness, root-mean-square roughness, average peak to valley height between five highest peaks and five deepest valleys within the sampling length, and skewness, in effect have been found to be poor representations of surface roughness. Another attribute of surface roughness should be taken into consideration, namely the lateral dimension that describes how frequently the surface height changes. It is known that the surface/interface topographies of all materials are fractals at the molecular level and can be represented by decimal number between 2 and 3. Thus, surface roughness characterization can be built on AFM measurements and subsequent fractal analysis approach, which takes into account both roughness heights and lateral dimensions. The results of fractal analysis of four wet granule samples, raw powder materials and freeze-dried mannitol powders reveals an intrinsic relationship between fractal dimension and the underlying processes which produced the material and formed the surface morphology.

The growing interest in the fractal approach for quantitative characterization of surface roughness can also be seen from a number of early and later works [29, 689, 938]. Here, the complementary usage of several methods must be emphasized, such as X-ray scattering and AFM with the latter providing a more adequate and accurate description of surface roughness allowing to imagine the evolution of the surface topography during various chemical and physical processes as described by Arnault et al. [29]. For instance, knowledge and control of the oxidation mechanisms at high temperature is a great challenge for aerospace and metallurgical industries. Numerous questions are still not resolved concerning the early stages of oxidation kinetics, their temperature dependence, surface and metal/oxide interface morphology. In this way, the study of the fractal surface parameters is valuable to follow the oxidation processes because the surface roughness evolution is in strong relation with the oxide growth mode.

The authors of the previous paper point out a substantial drawback of AFM, namely the small scan area available for fractal analysis. Fortunately, some present day SPM apparatus are capable of imaging areas spreading over several millimeters as described in [156] by Hosaka et al. The method of "Digital Probing" or "Recession Mode" AFM presented in this work is developed for measurements of high aspect ratio microelectronic structures without damage to the measured wafer. In contrast to other well-known methods and techniques, in this case a high aspect ratio AFM probe (with a "whisker" or even a nanotube) retracts far back (up to 2.1 µm) at every measured point of the scan after touching the surface at this point (with contact force within 2-20nN). This technique allows for measuring steep walls and deep trenches (90-160nm in width and 600nm in depth with angles of about 85° as depicted for the typical structure) and effectively suppresses AFM probe wear. The disadvantage of this approach is the very long scan time , for instance around 45 minutes to acquire a 256x256 pixel array. This is an example of using AFM in Critical Dimension Metrology (CDM) since proximal probing techniques are the only nondestructive control means applicable at the nanoscale.

Determining the structural accuracy of critical parts within optical spectrometers manufactured by the LIGA-process (involving deep X-ray lithography, electroforming and moulding) is successfully performed by AFM [1009]. The "heart" of the spectrometer is a self-focusing blazed diffraction grating whose structural accuracy and sidewall roughness determine the transmission, signal-to-noise ratio, peak intensity and partitioning of the intensity into the different optical orders of the spectrometer. The demanded measurement accuracy of the grating having 1.2µm step height and 6µm step width exceeds the resolution of optical microscopes as well as that of profilometers. Thus AFM becomes the method of choice.

The increasing significance of SPM in tribological investigations at the micro- and nanoscale is the consequence of the limitations in performance for other methods, their lack of resolution power or insufficiency of descriptive potential. For instance, several conventional techniques can be applied for calculation of the amount of material loss in tribological experiments such as stylus profilometry or laser profilometry. However, due to the ongoing reduction of tribologically stressed components and because the amount of wear often reaches values beyond the detection limit for this techniques Atomic Force Microscopy becomes the method of choice in wear investigations at the nanoscale. Among the known problems of AFM itself is the complexity of multiple measurements on the same sample area after processing the sample, say, using a tribometer. Schofer and Santner [681] use a specially designed stage on which both a stand-alone AFM and a tribometer can be mounted consecutively with high accuracy. This setup allows imaging the same surface section of a sample with an atomic force microscope before and after tribological stressing. The authors perform measurements of hardness indentations on a Si wafer with ultra-high precision and studied wear events due to the sliding motion on an AuNi coating and filled polymers for electrical contact systems. Also, means for accuracy improvement of quantitative wear analysis and possible error correction are considered in details.

The typical procedure of friction force measurements is described in a paper by Bhushan and Sundararajan 600. The AFM tip is scanned along the AFM cantilever axis to obtain the coefficient of friction and it is scanned orthogonally to the AFM cantilever axis to obtain friction force maps. The coefficient of friction is obtained from the slope of friction force data measured as a function of normal loads typically ranging from 50 to 250nN. This approach eliminates any differences in contributions due to the adhesive forces.

Measuring topography, characterization of friction and wear of amorphous carbon thin films for hard disk data storage applications is of great concern in the development of better overcoats (see also SPM in Data Storage section). Scanning Force Microscopy is an increasingly popular technique to assess film roughness, fractal dimension, or power spectral density. To reveal more subtle features, like topographic anisotropy, image processing is required. Schouterden and Lairson [1006] use digital Wiener filtering to reveal anisotropy in the AFM topography of supersmooth surfaces. Topography and frictional properties (contact forces between the AFM tip and the sample was of 1-10nN) of unworn surface and the surfaces worn for 240 and 1500sec. with sliding diamond counterbody (contact load of 2.4mN was applied) are measured, and the dependence of local friction force of the z-height and the crosscorrelation between friction and z-height is calculated. It is shown that wear introduces anisotropy on two different levels: directional (in-plane) and z-height anisotropy. Second derivative distributions of unworn surfaces with different wear tracks showed that wear makes the surface preferentially smoother in the wear direction. The local friction force as measured by LFM indicated a change in local surface topography or chemistry upon wear. Assuming the macroscopic friction force is proportional to the real area of contact authors proposed a simple wear model.

An attempt to apply Atomic Force Microscopy to a quantitative description of profiles and fracture surfaces of hard materials such as carbides is made by Cwajna and Roskosz [330]. The authors agree that the preparation of topography maps enables the determination of not only selected profiles but the entire surface of the investigated fracture and that high resolution is a beneficial feature of atomic force microscopy. However, it can be argued with the conclusion that no possibility of registration, analysis, and quantitative description of phases occurring on fracture surfaces, overlaps, and secondary cracks are possible with AFM because there is a number of additional modes and techniques such as Nanoindentation which are capable of providing all necessary information beyond topography. This is illustrated very well in a paper by Randall et al. [1450].

There is a vast class of crystals named ferroics. In general, it includes ferroelectrics, ferromagnetics and ferroelastics. The structural and/or physical properties of these crystals change strongly below a certain temperature. It is also well known that they exhibit similar structure to bulk material divided into domains having different electric, magnetic or mechanical properties. Investigation of the surface structure of ferroelectric and ferroelastic crystals is interesting because of some expectations that the surface structure can be correlated with the domain and/or domain boundary structures. Also, due to the high resolution of SPM atomic level corrugations can be monitored at their surfaces.

Ferroelastic crystals represent a relatively new class of ferroics whose history amounts to a little more than 40 years. Czajka et al. [335] explore the topography and frictional properties of freshly cleaved surfaces of K3Na(SeO4)2 (KNSe), NH4LiH3(SO4)4 (ALHS) and Gd2(MoO4)3 (GMO) in ambient and UHV conditions. Terraces separated by c/2 (KNSe) and c/4 (ALHS), where c is the biggest lattice constant before structural transformation, are observed indicating that a transition has occurred. Friction (Lateral) Force Microscopy measurements reveal substantially different friction properties of the terraces separated with a half lattice period in the c-axis direction. The authors suggest that this contrast is due to different molecular orientation invoked by the transition. The lateral force image of GMO shows a very distinct domain structure and the angle of 2.35° of a surface bend at the domain boundary is observed.

Earlier, stripes and needle-shaped domains are observed on the lead vanadate ferroelastic crystal surface by Bhalla et al. [151]. This suggests that the domain wall height gradually decreases and than vanishes approaching the tip of the needle shaped domain. These features can be most undesirable for some devices based on acousto-optic properties. The authors believe that the surface morphological differences on unit cell scale in the two domain regions, which finally result in a contrast in the AFM scans of the surface, may provide a unique insight in understanding the ferroelastic distortions of the lattice in ferroic crystals.

In some cases topographic as well as mechanical modes and techniques of Scanning Probe Microscopy allow revealing the properties of even magnetically or electrically active objects. For example, Morais et al. [336] use contact AFM to estimate the size distribution of magnetic nanoparticles in a magnetite-based magnetic fluid (MF) sample. It is known that the physical, chemical, and physico-chemical properties of such fluids are strongly influenced by the details of the distribution in size and shape of the dispersed colloidal nanomagnetic particles. The average particle size obtained from the AFM data is very close to that obtained from the direct magnetization experiments. The authors suppose that the higher standard deviation for the latter could be explained by the presence of agglomerates. Lacava et al. [632] explore AFM, transmission electron microscopy (TEM), and ferromagnetic resonance (FMR) methods for the same measurements. Compared to TEM, the AFM method shows a nanoparticle diameter reduction of 20% and increase in standard deviation of 15%. These differences are associated with the AFM tip and the magnetic nanoparticles concentration on the substrate.

Another example is an AFM study of the surface topography and domain structures of triglycin sulfate (TGS, (NH3CH2OO)3·H2SO4) by Tolstikhina et al. [1352]. This ferroelectric crystal is studied intensively on the macroscale. The grown crystals are investigated after annealing and g-irradiation at various doses. Images are obtained in contact, resonance, and lateral force modes. A classical lens-like domain oriented with the long axis of the lens parallel to the crystallographic a-axis is clearly seen on the LFM images. The domain contrasted with the surrounding matrix having the opposite polarization. An interesting substructure is observed within the domain: a number of round-shaped formations of opposite polarity of about 100-150nm in diameter are arranged like beads along the whole perimeter of the domain wall. These formations can serve as nuclei for subsequent repolarization. The authors state that imaging in all modes, especially in contact mode, tends to alter the pattern of the specimen polarization. Moreover, if optimum scanning conditions are found provided that the samples undergo specific treatment, a predetermined domain structure can be written on the ferroelectric surface.

A combination of AFM and LFM with a net constant force of about 80 nN is used by Ankudinov et al. [1342] to investigate cross-sections of ZnMgSSe- and BeMgZnSe-based laser diodes. Topographic singularities located in the vicinity of a quantum well active region are found and attributed to relaxation of relatively stressed layers after cleavage. Analysis of data obtained helps make the following observations: (1) an inequality in the surface morphology of the cladding layers of the studied S- and Be-containing heterostructures and (2) a dependence of the shape and height of the singularity at the waveguide position on the active region design. Thus, in contrast to SEM and TEM, using AFM and LFM the stress distribution across the structure as subnanometer-scale relief modulation at the structure cleavage plane can be successfully observed. It provides the basis for estimation of the influence of the material hardness on the cleavage surface morphology.

In numerous cases when a specimen can not be fragmented in order to be put onto an SPM stage, techniques of surface replication are available which are widely used for SEM and TEM studies. Campbell and Lankford [421] perform systematic investigation of AFM applicability for imaging replicated samples. It is shown that AFM of replicas offers higher resolution than that obtainable from replicas imaged by conventional (non-field emission) SEM. Direct measurements of vertical and lateral dimensions, and their angular relationships, are readily available, and the AFM images are free of electron optical and interaction artifacts. However, any dimensional measurement, taken below some critical scan size on a replica, has a large probability of being inaccurate since the replica is not a perfect "negative" copy of the surface from which it is taken. Thus, the resolution limit of AFM when applied to replicas is defined by the fidelity of the replica itself, rather than by the resolving ability of the AFM system and superior replication technology must be developed if replicas are to be useful in work that requires high resolution AFM measurements.

The properties of metal-metal oxide interfaces are of major importance in the field of supported metal heterogeneous catalysis, even in those cases where there is no strong chemical interaction between the two phases. Of these, metal-alumina systems are in widespread use, in both academic and technological applications. By means of Atomic Force Microscopy Bird et al. [439] explore the genesis of realistic Ag-a-alumina model catalysts from an aqueous precursor (AgNO3), using conditions identical to those used in the synthesis of practical dispersed catalysts. Authors selected the alumina substrates of two orientations. It is found that on the smooth (001) surface, precursor decomposition leads to formation of a quasi-2D Ag network that undergoes rapid sintering in oxygen at 780K to yield large isolated metal particles. Surprisingly, the same process on the step-kinked (11-20) surface leads to formation of quasi-1D Ag nanowires that decorate the step edges. Most interestingly, these nanowires are relatively stable against sintering in 1bar oxygen at 780K having 50-70nm in width and many hundreds of nanometers in length, suggesting a particularly favourable interaction between Ag and the (1-102) plane of a-alumina. Thus, Atomic Force Microscopy provides a viable method for investigating the genesis of realistic model metal-on-insulator catalysts from solution precursors.

Proximal probe techniques could serve as an excellent supplement to other commonly used surface analysis methods such as Scanning Electron Microscopy, Transmission Electron Microscopy, Electron Spectroscopy (AES and XPS), Secondary Ion Mass Spectrometry (SIMS) and others.

An excellent example of complementary usage of AFM and XPS inelastic peak shape analysis in a study of germanium deposited on Si(001) by electron beam evaporation is presented in the work of Simonsen et al. [274]. It is found that combining the two techniques gives much more detailed information on the nanostructure of the surface of semiconductor/semiconductor systems than AFM alone. XPS peak shape analysis provides chemical and in-depth information and an average island shape, while AFM gives detailed, local information on the island distribution, but no chemical information. In this sense, the two techniques complement each other very favourably.

Another example is a paper of Malherbe and Odendaal [1030] who use Auger Electron Spectroscopy and X-ray Photoelectron Spectroscopy together with AFM to assess the influence of ion bombardment on the structural and topographic characteristics of electronic materials and in particular compound semiconductors. It is found, for instance, that the extent of bombardment-induced topography depends primarily on the substrate material while the ion beam characteristics play only a secondary role. The work gives a survey of surface modification of many semiconductor materials (see the references therein).

Measuring elasticity/stiffness, hardness and adhesion

Development of powerful enhancements such as Phase Imaging [32, 665], Force Modulation Mode and others make Scanning Force Microscopy very sensitive to a number of different material properties. These enhancements allow for estimation and quantitative description of elasticity (or stiffness), hardness, adhesion, viscosity and other properties. Below, the most general definitions of the properties mentioned are formulated.

Hardness is the measure of a locally loaded region of a material to withstand external force keeping its structure and form unchanged.

Elasticity (stiffness) determines the material's relative measure to deform reversibly under applied loading.

Adhesion is the sticking ability of a species on the surface being investigated. Attractive forces may be of various nature such as those caused by electrostatic charges, capillary forces etc.

Viscosity defines the dynamics of a material's deformation (often flow), i.e. rheological properties.

As in the case of LFM, acquisition of data relating to these properties can often be performed simultaneously with topography allowing for significant improvement of contrast and resolution over conventional AFM modes. The problems of simultaneous acquisition of topography and material's properties have been analyzed by Burnham et al. [1410].

In the experiments for hardness determination AFM is usually used together with a technique named Nanoindentation [4, 634, 815, 872, 1035, 1219, 1450]. A typical nanoscopic indenter (the so-called Berkovich indenter) is a three-sided pyramidal single-crystal natural diamond tip mounted on the beam in such a way that one sharp edge is parallel to the long axis of the beam (though, this is taken into consideration only for wear and scratching experiments, which are often planned to be performed along with nanoindentation). The indenter stresses the surface of the material studied at various exactly maintained forces for about 1-2s. The indentation pit has a distinct geometry, which can be characterized using AFM with high precision. Moreover, AFM is the only method capable of exact geometry determination of such tiny areas. Nanohardness is calculated by dividing the loading force by the projected residual area of the indentation.

AFM/nanoindentation is the only method for hardness determination of ultrathin coatings such as hard disk protective carbon films. To exclude the influence of the film support layer the depth of nanoindentation should be several times (5-10) smaller than the film thickness. Indenters are capable of leaving pits as small as 1nm in depth, and therefore the above condition as a rule is observed well. In order to obtain an accurate relationship between the indentation depth and the projected contact area, indenter tip shape calibration needs to be carried out especially for ultrasmall penetration depths. The problem of determining the area function of the indenters is discussed in details by Herrmann et al. [1452] since geometry of the indenter tip is the most significant source of uncertainty in nanoindentation measurements. Authors draw attention to a number of other problems related to the accuracy of this method.

Nanohardness has been found to vary with indentation depth (and, consequently, loading) especially for hard and fragile materials such as monocrystalline silicon. It tends to decrease with increasing the applied loading. For example, for (111)-oriented silicon it decreases by 5GPa after loading increase of about 35mN according to Bhushan and Koinkar [1279]. Hardness change for (100)-oriented silicon is not very dramatic [1280]. The comparison is presented in Fig. 2.

![Fig. 2. Nanohardness of a-(111) and b-(100) oriented silicon as a dependence of indentation loading (a - [1279], b - [1280]) Fig. 2. Nanohardness of a-(111) and b-(100) oriented silicon as a dependence of indentation loading (a - [1279], b - [1280])](/uploads/gallery/nanohardness-of-a-111-and-b-100-20120928120932.gif)

Fig. 2. Nanohardness of a-(111) and b-(100) oriented silicon as a dependence of indentation loading (a - [1279], b - [1280])

The decrease in hardness can be explained by formation of multiple defects in the local area as a result of the loading that lead to degradation of the local structure. This degradation, perhaps, goes much more readily in the case when the symmetries of the surface and the indenter coincide in the contact direction, as can be seen in the case of (111)-oriented silicon.

Nonetheless, inducing defects may substantially extend the sample's hardness and corresponding tribological properties such as wear resistance. Ion implantation is the most commonly used method for this purpose especially in application to polymers.

An ideal solution for AFM/nanoindentation apparatus would be a system, which exploits one and the same indenter for both indenting and imaging of the indentation produced. Unfortunately, it is practically impossible to unite the advantages of nanosensing capability of an AFM probe tip with the extraordinary hardness of an indenter. Therefore, solutions have to be found in combination of both indentation and AFM imaging apparatus into a single device, as for example presented by Randall et al. [1450].

Besides hardness, the Young's modulus of elasticity can be obtained from the slope of the unloading curve [1035]. Typical loading(unloading)-displacement curves for relatively hard materials are depicted in Fig. 3.

Fig. 3. A typical loading-displacement curve.

Their hysteretic appearance means that deformation is not fully elastic and partially destructive. Inelastic deformation can be reduced using specially flattened tips but in this case the morphology of the surface and the flat portion of the tip become additional factors influencing the accuracy of the final result [2623, 2624]. For compliant materials such as polymer blends, magnetic tapes etc. loading and unloading curves are practically identical.

In polymer applications nanoindentation is used mainly for determination of elasticity and viscoelasticity [1219] since the deformation has mainly reversible elastic character. Because nanoindentation is a local point technique it is not suitable for mapping variations of hardness, elasticity and other properties on the sample surface. Localized surface elasticity maps can be obtained using the force-modulation or phase imaging techniques [502, 1221, 1222, 2802, 2803].

The systematic analysis of Force Modulation AFM (FM-AFM) is presented in the paper of Li et al. [502]. FM-AFM reveals the major topographic features of Contact Mode AFM (CM-AFM) but allows greater resolution for sample features that are difficult for CM-AFM, and also allows continuous two-dimensional mapping of local mechanical properties on a scale of nanometers that CM-AFM, Tapping Mode AFM (TM-AFM) and any other techniques, are not capable of sensing. This information can be used to elucidate other properties of the investigated surface, such as crystallinity variations, phase separation and distribution, and mechanisms of formation of deposited films.

Variations in the (usually sinusoidal) oscillation amplitude introduced by a special bimorph well below the resonance frequency of the cantilever are used for measuring local variations in hardness or stiffness of the samples. (In the case of qualitative measurements it is hard to distinguish between hardness and stiffness). Very soft samples do not affect greatly the oscillation amplitude since the tip penetrates the surface relatively deeply. The changes in oscillation amplitude for hard samples are more significant showing anharmonic distortions. Along with amplitude and height (topography) imaging, the phase detection channel can also be used to measure some other characteristics such as viscosity.

For electrodeposited cerium oxide considered in this paper, FM-AFM provides very distinct grain boundaries while many grains, up to a few hundred nanometers diameter are not resolved in the height images. Some of the grains appear monolithic, but others are further composed of a number of aggregated fine grains as could not be observed in corresponding height images. The overall grain structure suggests that the film is deposited through a nucleation mechanism, rather than a "general growth" process in which the deposit is added to the substrate surface uniformity to produce an even, continuous film.

The nature of adhesive interactions between the tip and the sample surface is very multicomponent and complicated [251, 407, 436, 443]. There is no ubiquitous measure for adhesion and it is too difficult to give comprehensive and at the same time exact definition of this "property".

Ouyang et al. [569] consider three main driving forces of adhesive interactions: the van der Waals force, the electrostatic force, and the capillary force of a water film on a solid surface. The authors aim to distinguish quantitatively among the contributions of each force to the total adhesion for various materials and ambient conditions by regarding the AFM tip as a standard. The adhesive forces are determined by measuring the pull-off forces between the tip and the sample surface in a so-called Force Calibration Mode of AFM. Typical shapes of curves for this mode are shown in Fig. 4.

Fig. 4. Typical curves of tip deflection as a function of Z-piezo travel.

The small negative bending of the AFM cantilever just before the beginning of positive deflection, depicted as a little pit in the loading curve, is attributed to electrostatic and van der Waals forces which cause attraction of the tip as it closely approaches to the sample surface. Adhesiveness is proportional to the amount of Z-piezo travel DZ on the unloading curve from the point of zero deflection (A) to the point of final release of the cantilever after pull-off from the surface (B).

The differences in contributions of the forces mentioned above have been shown to vary depending upon the material to a great extent. Three lamellar materials are taken for the study: mica, graphite and MoS2. It is found that capillary forces at relative humidity of about 50% play significant role for mica and graphite, whereas for MoS2 they are the smallest. Electrostatic forces are dominant for MoS2 and it is known that this material is usually studied while immersed in liquid to remove unwanted electrostatic and capillary forces. The intensity of capillary forces strongly depends on the hydrophilicity of the surface studied as investigated, for example, by Moon et al. (see [1489] in the SPM-based nanotechnology section). Graphite showed the minimum overall adhesiveness and minimum electrostatic and van der Waals forces contributions in particular. When selection is necessary among the lamellar materials according to their lubricating properties graphite should be chosen since the large contribution of electrostatic forces in the case of MoS2 during friction introduce a hazard for applications critical to electrostatic discharges such as oil and gas mining. In contrast to graphite mica shows the most pronounced adhesive properties for its high van der Waals force that is not changeable by atmosphere. Authors conclude that the conditions for low adhesions are both the low van der Waals interaction and the proper atmosphere.

Examining the slight changes in the slope of loading and unloading curves in Fig 4. one can in principle assess an indentation measure of the tip into the surface of compliant materials such as polymers, as was performed by Bhushan et al. [1224]. Later Vanlandingham et al. [686] examine in details this repulsive region of the force curves. In this paper a technique is developed that (1) relates the elastic modulus of the sample to the sample response measured using AFM force curves, and (2) emphasizes the importance of the relative stiffness of the cantilever probe and the sample to the determination of elastic modulus. The authors use two separate cantilevers having spring constants of 1 and 60N/m respectively for measuring indentations on a number of polymer samples. These are polyurethanes, visible-light-cured acrylated epoxies, thermally cured epoxies and polyetheretherketone (PEEK).

The elastic moduli of these polymer samples are determined independently using dynamic mechanical analysis, and range from 0.02 to 3.0GPa. In order to provide a calibration reference, titanium (E>100GPa) is used as an "infinitely stiff" material for the determination of conversion and amplification factors of the registration system (in effect, the AFM cantilever bending along the ordinate axis in Fig. 3 is measured in terms of the voltage generated in the photodiode by light reflected from the backside of the cantilever, so conversion parameters from V to nm should be taken into account). The ratio of the real slope to the maximum possible one is called the reduction factor f. This factor is observed to increase as the stiffness of the sample increased. The response of polymers with moduli greater than 0.5 and 0.1 GPa for 60 N/m and 1N/m probes respectively, approaches that of the "infinitely stiff" titanium sample. Therefore, above these modulus values, samples of differing moduli become indistinguishable. The use of the reduction factor, however, does not take into account the actual indentation process. It has been shown that when the amount of probe tip displacement Dt exceeds the indentation displacement Di, their relation Di/Dt becomes insensitive to modulus changes. In other words, the force applied by the probe to the sample surface is insufficient to produce adequate deformation of the stiffer samples. Because the60 N/m AFM probe applies higher forces to the sample than does the 1N/m AFM probe for a given tip displacement, it is sensitive up to higher modulus values and thus can be used to evaluate higher modulus samples. Thus, using very stiff AFM cantilevers (~500N/m) modulus changes in polymers commonly used in engineering applications can be measured. The authors suppose that these calibration curves will allow for the study of modulus changes in heterogeneous regions typically found in polymer blends, adhesive systems, coatings, and in the vicinity of fibers of composite materials.

Please, send all comments and suggestions concerning these pages to info@mikromasch.com.

| ID | Reference list (newly come references are marked red) |

| 1076 | A hybrid scanning force and light microscope for surface imaging and three dimensional optical sectioning in differential interference contrast A. Stemmer J. Microsc. 178 (1995) 28 |

| 1003 | A study comparing measurements of roughness of silicon and SiO2 surfaces and interfaces using scanning probe microscopy and neutron reflectivity A. Crossley, S.J. Sofield, M.T. Hutchings, J.P. Goff, A.C.I. Lake, A. Menelle Journal of Non-Crystalline Solids, 187 (1995), 221-226 |

| 1209 | AFM and light scattering measurements of optical thin films for applications in the UV spectral region S. Jackobs, A. Duparre, H. Truckenbrodt Internat. Journ. of Machine Tools and Manufacturing 35 (1997) 2, p. 147-153 |

| 1352 | AFM characterization of domain structure of ferroelectric TGS crystals on a nanoscale A.L. Tolstikhina, N.V. Belugina, S.A. Shikin Ultramicroscopy 82 (2000) 149-152 |

| 267 | AFM studies of polypyrrole film surface morphology II. Roughness characterization by the fractal dimension analysis Q. Hong, R.G. Compton, J. Tamm, T. Silk Synthetic Metals, 93 (1998), 1, 65-71 |

| 118 | AFM studies of the nucleation and growth mechanisms of macromolecular crystals Y.G. Kuznetsov, A.J. Malkin, A. McPherson Journal of Crystal Growth, 196 (1999), 2-4, 489-502 |

| 149 | AFM, SEM, EDX and HRTEM study of the crystalline growth rate anisotropy-induced internal stress and surface roughness of YBaCuO thin film F. Pailloux, R.J. Gaboriaud, C. Champeaux, A. Catherinot Materials Characterization, 46 (2001), 1, 55-63 |

| 297 | AFM-study of sticking effects for microparts handling H. Von Kanel, B. Vogeli Wear, 238 (2000), 1, 20-24 |

| 1006 | Anisotropy in wear processes measured by scanning probe microscopy K. Schouterden, B.M. Lairson Thin Solid Films, 340 (1999), 1-2, 40-44 |

| 326 | Application of atomic force microscopy for microindentation testing M. Petzold, J. Landgraf, M. Futing, J.M. Olaf Thin Solid Films, 264 (1995), 2, 153-158 |

| 330 | Application of confocal laser scanning microscopy, atomic force microscopy, and the profilometric method in quantitative fractography J. Cwajna, S. Roskosz Materials Characterization, 46 (2001), 2-3, 183-187 |

| 1009 | Application of Scanning Probe Microscopy for the determination of the structural accuracy of high aspect ratio microstructures S. Achenbach, J. Mohr, F.J. Pantenburg Microelectronic Engineering, 53 (2000), 1-4, 637-640 |

| 812 | Atomic and chemical resolution in scanning force microscopy on ionic surfaces A.I. Livshits, A.L. Shluger Applied Surface Science, 141 (1999), 3-4, 274-286 |

| 335 | Atomic force microscopy and friction force microscopy studies of ferroelastic crystal surfaces R. Czajka, S. Mielcarek, B. Mroz, S. Szuba, A. Kasuya, S. Kaszczyszyn Wear, 238 (2000), 1, 34-39 |

| 336 | Atomic force microscopy and magnetization investigation of a water-based magnetic fluid P.C. Morais, B.M. Lacava, A.F. Bakuzis, L.M. Lacava, L.P. Silva, R.B. Azevedo, Z.G.M. Lacava, N. Buske, W.C. Nunes, M.A. Novak Journal of Magnetism and Magnetic Materials, 226 (2001), 1899-1900 |

| 345 | Atomic force microscopy and X-ray diffraction study of surface and interface roughness in Nb/Cu multilayers K. Temst, M.J. Van Bael, B. Wuyts, C. Van Haesendonck, Y. Bruynseraede, D.G. De Groot, N.J. Koeman, R.P. Griessen Journal of Magnetism and Magnetic Materials, 156 (1996), 1-3, 109-110 |

| 365 | Atomic force microscopy investigation of the surface topography and adhesion of nickel nanoparticles to submicrospherical silica D. Aurbach, S. Ramesh, A. Gedanken, Y. Cohen Chemical Physics Letters, 287 (1998), 3-4, 461-467 |

| 378 | Atomic force microscopy of high velocity cluster impact induced nanostructures P. Von Blanckenhagen, A. Gruber, J. Gspann Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 122 (1997), 3, 322-324 |

| 387 | Atomic force microscopy on cross-sections of optical coatings: a new method A. Duparre, C. Ruppe, K.A. Pischow, M. Adamik, P.B. Barna Thin Solid Films, 261 (1995), 1-2, 70-75 |

| 407 | Atomic force microscopy study of polypropylene surfaces treated by UV and ozone exposure: modification of morphology and adhesion force H.-Y. Nie, M.J. Walzak, B. Berno, N.S. McIntyre Applied Surface Science, 144-145 (1999), 627-632 |

| 421 | Atomic force microscopy using plastic replicas J. B. Campbell, J. Lankford Journal of Materials Science (full set), 35 (2000), 3, 757-765 |

| 58 | Atomic resolved imaging of cleaved NiO(100) surfaces by NC-AFM H. Hosoi, K. Sueoka, K. Hayakawa, K. Mukasa Applied Surface Science, 157 (2000), 4, 218-221 |

| 208 | Atomic structure of loaded crack tip by AFM C. Wuyang, G. Jingjiao, W. Chen Scripta Materialia, 39 (1998), 9, 1211-1214 |

| 1224 | Atomic-scale friction measurements using friction force microscopy. Part II. Application to magnetic media B. Bhushan, J. Ruan ASME J. Tribol. 116 (1994) 389-396 |

| 436 | Barium stearate Langmuir-Blodgett films investigated by mapping adhesion forces with atomic force microscopy B. Pignataro, C. Consalvo, G. Compagnini, A. Licciardello Chemical Physics Letters, 299 (1999), 5, 430-436 |

| 815 | Between nanoindentation and scanning force microscopy: measuring mechanical properties in the nanometer regime S.P. Baker Thin Solid Films, 308-309 (1997), 1-4, 289-296 |

| 439 | Catalyst genesis studied by atomic force microscopy D.P.C. Bird, C.M.C. de Castilho, R.M. Lambert Surface Science, 449 (2000), 1-3, L221-L227 |

| 443 | Characterization of glass-epoxy adhesion using JKR methods and atomic force microscopy D.L. Woerdeman, N. Amouroux, V. Ponsinet, G. Jandeau, H. Hervet, L. Leger Composites Part A: Applied Science and Manufacturing, 30 (1999), 1, 95-109 |

| 462 | Contact and non-contact mode imaging by atomic force microscopy S. Morita, S. Fujisawa, E. Kishi, M. Ohta, H. Ueyama, Y. Sugawara Thin Solid Films, 273 (1996), 1-2, 138-142 |

| 7 | Contrast inversion in nc-AFM on Si(111)7x7 due to short-range electrostatic interactions M. Guggisberg, O. Pfeiffer, S. Schar, V. Barwich, M. Bammerlin, C. Loppacher, R. Bennewitz, A. Baratoff, E. Meyer Applied Physics A: Materials Science & Processing, 72 (2001), 7, S19-S22 |

| 826 | Cooling crystallization experiments observed by in situ scanning force microscopy R. Lacmann, S. Kipp Journal of Crystal Growth, 160 (1996), 3-4, 320-329 |

| 1342 | Cross-sectional atomic force microscopy of ZnMgSSe and BeMgZnSe-based laser diodes A. V. Ankudinov, A. N. Titkov, T. V. Shubina, S. V. Ivanov, P. S. Kop'ev, H.-J. Lugauer, G. Reuscher, M. Keim, A. Waag, and G. Landwehr Appl. Phys. Lett., 75 (1999) 17, 2626-2628 |

| 471 | Determination of the surface area of annealed continuous gold film and pyrex glass in situ by the BET adsorption isotherm and ex situ by Atomic Force Microscopy in air L. Stobinski, L. Zommer Applied Surface Science, 135 (1998), 1-4, 8-14 |

| 1350 | Dynamic oxide interfaces by microscopic techniques at high resolutions Y. Iwasawa Surface Science 402-404 (1998) 8-19 |

| 1412 | Elastic and Shear Moduli of Single-Walled Carbon Nanotube Ropes J.-P. Salvetat, G. A. D. Briggs, J.-M. Bonard, R. R. Bacsa, A. J. Kulik, Th. Stöckli, N. A. Burnham and László Forró Phys. Rev. Lett. 82 (1999), 5, 944-947 |

| 1650 | Entropic Elasticity of Single Polymer Chains of Poly(methacrylic acid) Measured by Atomic Force Microscopy C. Ortiz and G. Hadziioannou Macromolecules 32 (1999), 780-787 |

| 158 | Evaluation and fabrication of AFM array for ESA-Midas/Rosetta space mission W. Barth, T. Debski, N. Abedinov, T. Ivanov, H. Heerlein, B. Volland, T. Gotszalk, I.W. Rangelow, K. Torkar, K. Fritzenwallner, P. Grabiec, K. Studzinska, I. Kostic, P. Hudek Microelectronic Engineering, 57-58 (2001), 825-831 |

| 151 | Ferroelastic domain study by atomic force microscope (AFM) A.S. Bhalla, G. Raina, S.K. Sharma Materials Letters, 35 (1998), 1-2, 28-32 |

| 502 | Force modulation atomic force microscopy: background, development and application to electrodeposited cerium oxide films F.-B. Li, G.E. Thompson, R.C. Newman Applied Surface Science, 126 (1998), 1-2, 21-33 |

| 505 | Fractal Analysis of Pharmaceutical Particles by Atomic Force Microscopy Tonglei Li, Kinam Park Pharmaceutical Research, 15 (1998), 8, 1222-1232 |

| 507 | Frequency modulation detection atomic force microscopy in the liquid environment S.P. Jarvis, T. Ishida, T. Uchihashi, Y. Nakayama, H. Tokumoto Applied Physics A: Materials Science & Processing, 72 (2001), 7, S129-S132 |

| 846 | Friction and head and disk interface durability in contact recording K. Schouterden, B.M. Lairson, C.S. Gudeman, K. Chun Wear, 216 (1998), 1, 70-76 |

| 849 | Glass and Structural Transitions Measured at Polymer Surfaces on the Nanoscale R. M. Overney, C. Buenviaje, R. Luginbuhl, F. Dinelli Journal of Thermal Analysis and Calorimetry, 59 (2000), 1/2, 205-225 |

| 518 | Guidelines for the achievement of true atomic resolution with noncontact atomic force microscopy S. Morita, Y. Sugawara Applied Surface Science, 140 (1999), 3-4, 406-410 |

| 4 | Hardness and modulus of the lamellar microstructure in PST-TiAl studied by nanoindentations and AFM M. Goken, M. Kempf, W.D. Nix Acta Materialia, 49 (2001), 5, 903-911 |

| 61 | High-resolution imaging of organic monolayers using noncontact AFM T. Uchihashi, T. Ishida, M. Komiyama, M. Ashino, Y. Sugawara, W. Mizutani, K. Yokoyama, S. Morita, H. Tokumoto, M. Ishikawa Applied Surface Science, 157 (2000), 4, 244-250 |

| 1093 | Imaging crystals, polymers, and processes in water with the atomic force microscope B. Drake, C.B. Prater, A.L. Weisenhorn, S.A.C. Gould, T.R. Albrecht, C.F. Quate, D.S. Cannell, H.G. Hansma, P.K. Hansma Science 243 (1989), 1586-1588 |

| 59 | Imaging of fullerene molecules on Si(111)-7x7 surface with NC-AFM K. Kobayashi, H. Yamada, T. Horiuchi, K. Matsushige Applied Surface Science, 157 (2000), 4, 228-232 |

| 546 | In situ atomic force microscopy studies of surface morphology, growth kinetics, defect structure and dissolution in macromolecular crystallization A.J. Malkin, A. McPherson, Y.G. Kuznetsov Journal of Crystal Growth, 196 (1999), 2-4, 471-488 |

| 1225 | In situ surface characterization of a binary aluminum alloy during tensile deformation W. Tong, L.G. Hector Jr., H. Weiland, L.F. Weiserman Scripta Materialia 36 (1997) 1339-1344 |

| 569 | Investigation of micro-adhesion by atomic force microscopy Q. Ouyang, K. Ishida, K. Okada Applied Surface Science, 169-170 (2001), 644-648 |

| 573 | Investigation of the stiffness change in, the indentation force and the hydrophobic recovery of plasma-oxidized polydimethylsiloxane surfaces by tapping mode atomic force microscopy G. Bar, L. Delineau, A. Hafele, M.-H. Whangbo Polymer, 42 (2001), 8, 3627-3632 |

| 1030 | Ion sputtering, surface topography, SPM and surface analysis of electronic materials J.B. Malherbe, R.Q. Odendaal Applied Surface Science, 144-145 (1999), 192-200 |

| 1308 | Lateral force microscopy - A quantitative approach C.T. Gibson, G.S. Watson, S. Myhra Wear, 213 (1997), 1-2, 72-79 |

| 859 | Lateral stiffness: A new nanomechanical measurement for the determination of shear strengths with friction force microscopy R. W. Carpick, D. F. Ogletree and M. Salmeron Appl. Phys. Lett. 70 (1997), 1548 |

| 868 | Layer growth in collapsed liquid crystal monolayers studied by scanning force microscopy J. Fang, C.M. Knobler, H. Yokoyama Physica A: Statistical Mechanics and its Applications, 244 (1997), 1-4, 91-98 |

| 1222 | Local elasticity and lubrication measurements using atomic force and friction force microscopy at ultrasonic frequencies V. Scherer, B. Bhushan, U. Rabe, W. Arnold IEEE Trans. Mag. 33 (1997) 4077-4079 |

| 583 | Local elasticity measurement on polymers using atomic force microscopy H.-Y. Nie, W. Mizutani, H. Tokumoto, M. Motomatsu Thin Solid Films, 273 (1996), 1-2, 143-148 |

| 1411 | Local mechanical spectroscopy with nanometer-scale lateral resolution F. Oulevey, G. Gremaud, A. Se´moroz, A. J. Kulik, N. A. Burnham, E. Dupas, and D. Gourdon Rev. Sci. Instrum., 69 (1998), 5, 2085-2094 |

| 872 | Localised micro-hardness measurements with a combined scanning force microscope/nanoindentation system N.X. Randall, R. Christoph, C. Julia-Schmutz, S. Droz Thin Solid Films, 290-291 (1996), 348-354 |

| 1221 | Localized surface elasticity measurements using an atomic force microscope D. DeVecchio, B. Bhushan Rev. Sci. Instrum. 68 (1997) 4498-4505 |

| 2 | Low and high cycle fatigue - a continuum supported by AFM observations S.E. Harvey, D.E. Kramer, W.W. Gerberich, J.W. Hoehn Acta Materialia, 46 (1998), 14, 5007-5021 |

| 1384 | Mapping and control of atomic force on Si(111)√3×√3-Ag surface using noncontact atomic force microscope S. Morita and Y. Sugawara Ultramicroscopy, 91 (2002) 1-4, pp. 89-96 |

| 1418 | Mapping and control of atomic force with noncontact atomic force microscopy Seizo Morita and Yasuhiro Sugawara RIKEN Review, 36 (2001), 3-5 |

| 1410 | Materials' properties measurements: Choosing the optimal scanning probe microscope configuration N. A. Burnham, G. Gremaud, A. J. Kulik, P.-J. Gallo, and F. Oulevey J. Vac. Sci. Technol. B14 (1996), 2, 1308-1312 |

| 590 | Measurement of surface roughness by atomic force microscopy and Rutherford backscattering spectrometry of CdS nanocrystalline films S.N. Sahu, S.N. Sarangi, K.K. Nanda Applied Surface Science, 133 (1998), 4, 293-297 |

| 592 | Measurements of elastic properties of ultra-thin diamond-like carbon coatings using atomic force acoustic microscopy S. Amelio, A.V. Goldade, U. Rabe, V. Scherer, B. Bhushan, W. Arnold Thin Solid Films, 392 (2001), 1, 75-84 |

| 593 | Measuring elasticity of biological materials by atomic force microscopy G. Semenza, A. Vinckier FEBS Letters, 430 (1998), 1-2, 12-16 |

| 1386 | Mechanical property measurements of nanoscale structures using an atomic force microscope Sriram Sundararajan, Bharat Bhushan, Takahiro Namazu and Yoshitada Isono Ultramicroscopy, 91 (2002) 1-4, pp. 111-118 |

| 600 | Micro/nanoscale friction and wear mechanisms of thin films using atomic force and friction force microscopy B. Bhushan, S. Sundararajan Acta Materialia, 46 (1998), 11, 3793-3804 |

| 1034 | Micro-indentation and scanning probe microscopy to assess multilayer magnetic film damage T.-W. Wu, J. Frommer Journal of Magnetism and Magnetic Materials, 219 (2000), 1, 142-152 |

| 620 | Molecularly resolved observation of surface reconstruction of C60 epitaxial films by atomic force microscopy A. Fujishima, Y. Kim, K. Hashimoto, L. Jiang, T. Iyoda Surface Science, 385 (1997), 2-3, l945-l951 |

| 1373 | Monitoring high-temperature solid-solid phase transitions of HMX with atomic force microscopy Brandon L. Weeks, Chantel M. Ruddle, Joseph M. Zaug and Debra J. Cook Ultramicroscopy, 93 (2002) 1, pp. 19-23 |

| 1370 | Morphology and roughness of high-vacuum sublimed oligomer thin films F. Biscarini, P. Samorí, A. Lauria, P. Ostoja, R. Zamboni, C. Taliani, P. Viville, R. Lazzaroni, J. L. Brédas Thin Solid Films, 284-285 (1996) 439-443 |

| 626 | Morphology of dual beam ion sputtered films investigated by atomic force microscopy C.-C. Lee, J.-C. Hsu, D.T. Wei, J.-H. Lin Thin Solid Films, 308-309 (1997), 1-4, 74-78 |

| 1035 | Nano- to microscale wear and mechanical characterization using scanning probe microscopy B. Bhushan Wear, 251 (2001), 1-12, 1105-1123 |

| 1280 | Nano/picoindentation measurement using a capacitive transducer system in atomic force microscopy B. Bhushan, A.V. Kulkarni, W. Bonin, J.T. Wyrobek Philos. Mag. 74 (1996) 1117-1128 |

| 628 | Nano-indentation, scratching and atomic force microscopy for evaluating the mar resistance of automotive clearcoats: study of the ductile scratches P. Bertrand-Lambotte, J.L. Loubet, C. Verpy, S. Pavan Thin Solid Films, 398-399 (2001), 306-312 |

| 1279 | Nanoindentation hardness measurements using atomic force microscopy B. Bhushan, V.N. Koinkar Appl. Phys. Lett. 64 (1994) 1653-1655 |

| 1219 | Nanoindentation of Polymers: An Overview VanLandingham M. R., Villarrubia J. S., Guthrie W. F., Meyers G. F. Advances in Scanning Probe Microscopy of Polymers. Proc. of Macromolecular Symposia, Volume 167 (2001), pp. 15-44 |

| 632 | Nanoparticle sizing: a comparative study using atomic force microscopy, transmission electron microscopy, and ferromagnetic resonance L.M. Lacava, B.M. Lacava, R.B. Azevedo, Z.G.M. Lacava, N. Buske, A.L. Tronconi, P.C. Morais Journal of Magnetism and Magnetic Materials, 225 (2001), 1-2, 79-83 |

| 634 | Nanoscale mechanical property measurements using modified atomic force microscopy A.V. Kulkarni, B. Bhushan Thin Solid Films, 290-291 (1996), 206-210 |

| 274 | Nanostructure of Ge deposited on Si(001): a study by XPS peak shape analysis and AFM A.C. Simonsen, M. Schleberger, S. Tougaard, J.L. Hansen, A.N. Larsen Thin Solid Films, 338 (1999), 1-2, 165-171 |

| 639 | New applications in studies of waterborne coatings by atomic force microscopy A.G. Gilicinski, C.R. Hegedus Progress in Organic Coatings, 32 (1997), 1-4, 81-88 |

| 885 | New opportunities in automotive tribology Mark P. Everson, Hiroko Ohtani Tribology Letters, 5 (1998), 1, 1-12 |

| 1450 | Novel nanoindentation method for characterising multiphase materials N.X. Randall, C. Julia-Schmutz, J.M. Soro, J. von Stebut, G. Zacharie Thin Solid Films, 308-309 (1997), 1-4, 297-303 |

| 1363 | Nucleation and growth of PbS nanocrystals and simulation of X-ray diffraction patterns V.S. Gurin Journal of Crystal Growth 191 (1998) 161-165 |

| 658 | Observations using atomic force microscopy of surface-relief associated with deformation in cube-oriented single crystals N. Stanford, M. Ferry Scripta Materialia, 44 (2001), 6, 941-946 |

| 661 | On the roughness of ideally planar H-Si(111) surfaces. An atomic force microscopy approach P. Dumas, F. Salvan, M. Ramonda Surface Science, 411 (1998), 1-2, L839-L843 |

| 665 | Phase imaging and stiffness in tapping-mode atomic force microscopy M.-H. Whangbo, S.N. Magonov, V. Elings Surface Science, 375 (1997), 2-3, l385-l391 |

| 32 | Phase imaging as an extension to tapping mode AFM for the identification of material properties on humidity-sensitive surfaces I. Schmitz, M. Schreiner, G. Friedbacher, M. Grasserbauer Applied Surface Science, 115 (1997), 2, 190-198 |

| 891 | Preparation and characterization of low-dimensional nanostructures L. Augustin, L.F. Chi, H. Fuchs, S. Hoppner, S. Rakers, C. Rothig, T. Schwaack, F. Starrberg Applied Surface Science, 141 (1999), 3-4, 219-227 |

| 676 | Probing the microelastic properties of nanobiological particles with tapping mode atomic force microscopy L. Shao, N.J. Tao, R.M. Leblanc Chemical Physics Letters, 273 (1997), 1-2, 37-41 |

| 1452 | Progress in determination of the area function of indenters used for nanoindentation K. Herrmann, N.M. Jennett, W. Wegener, J. Meneve, K. Hasche, R. Seemann Thin Solid Films, 377-378 (2000), 394-400 |

| 156 | Proposal for new atomic force microscopy (AFM) imaging for a high aspect structure (digital probing mode AFM) S. Hosaka, T. Morimoto, K. Kuroda, H. Kunitomo, T. Hiroki, T. Kitsukawa, S. Miwa, H. Yanagimoto, K. Murayama Microelectronic Engineering, 57-58 (2001), 651-657 |

| 680 | Quantitative study by atomic force microscopy and spectrophotometry of the roughness and brightness of electrodeposited nickel in the presence of additives M. Troyon, V. Darrort, J. Ebothe, C. Bissieux, C. Nicollin Thin Solid Films, 265 (1995), 1-2, 52-57 |

| 681 | Quantitative wear analysis using atomic force microscopy J. Schofer, E. Santner Wear, 222 (1998), 2, 74-83 |

| 686 | Relating elastic modulus to indentation response using atomic force microscopy M. R. Vanlandingham, S. H. McKnight, G. R. Palmese, R. F. Eduljee, J. W. Gillespie, Jr. R. L. McCulough Journal of Materials Science Letters, 16 (1997), 2, 117-119 |

| 251 | Role of the adhesion between a nanotip and a soft material in tapping mode AFM F. Dubourg, J.P. Aime Surface Science, 466 (2000), 1-3, 137-143 |

| 688 | Roughness analysis of optical films and substrates by atomic force microscopy C. Ruppe, A. Duparre Thin Solid Films, 288 (1996), 1-2, 8-13 |

| 31 | Roughness and chemistry of silicon and polysilicon surfaces etched in high-density plasma: XPS, AFM and ellipsometry analysis L. Rolland, C. Vallee, M.-C. Peignon, C. Cardinaud Applied Surface Science, 164 (2000), 1-4, 147-155 |

| 277 | Roughness and critical exponents analysis of diamond films by AFM imaging M.C. Salvadori, M.G. Silveira, M. Cattani Thin Solid Films, 354 (1999), 1-2, 1-4 |

| 689 | Roughness determination of plasma-modified surface layers with atomic force microscopy N. Almqvist, M. Rubel, P. Wienhold, S. Fredriksson Thin Solid Films, 270 (1995), 1-2, 426-430 |

| 29 | Roughness fractal approach of oxidised surfaces by AFM and diffuse X-ray reflectometry measurements J.C. Arnault, A. Knoll, E. Smigiel, A. Cornet Applied Surface Science, 171 (2001), 3-4, 189-196 |

| 1052 | Scanning probe microscopy for nanometer inspections and industrial applications W. Gutmannsbauer, H.J. Hug, E. Meyer Microelectronic Engineering, 32 (1996), 1-4, 389-409 |

| 1448 | Scanning Probe Microscopy of High-Temperature Superconductors de Lozanne Supercond. Sci. Technol. 12 (1999), 4, pp. R43-R56 |

| 1063 | Scanning probe microscopy study of the interface roughness dependence of the magnetism of metallic multilayers K. Mukasa, M. Matsui, Y. Yamada, G. Eilers Applied Surface Science, 142 (1999), 1-4, 527-531 |

| 924 | Semi-quantitative mechanical characterisation of fibre composites in the sub-micron-range by SFM K. Schneider, V. Herrmann Composites Part A: Applied Science and Manufacturing, 32 (2001), 12, 1679-1687 |

| 700 | Site discrimination of adatoms in Si(111)-7 x 7 by noncontact atomic force microscopy N. Nakagiri, K. Okiguchi, H. Sugimura, M. Suzuki Surface Science, 373 (1997), 1, l329-l332 |

| 930 | Stress induced movement of ferroelastic domain walls in BaTiO3 single crystals evaluated by scanning force microscopy J. Munoz-Saldana, G.A. Schneider, L.M. Eng Surface Science, 480 (2001), 1-2, L402-L410 |

| 1066 | Studies of microhardness and mar resistance using a scanning probe microscope David Rey, Jonathan Stoeckel, Gregoire Malandain, Nicholas Ayache Lecture Notes in Computer Science, 2208 (2001), 1232 |

| 721 | Submolecular resolution of single macromolecules with atomic force microscopy D.M. Czajkowsky, Z. Shao FEBS Letters, 430 (1998), 1-2, 51-54 |

| 1413 | Surface Forces and Adhesion N.A. Burnham and A.J. Kulik in "Handbook of Micro/Nanotribology", B. Bhushan, ed., 1997, CRC Press, Boca Raton, FL. |

| 735 | Surface roughness characterization of Nicalon(R) and HI-Nicalon(R) ceramic fibers by atomic force microscopy N. Chawla, J.F. Mansfield, J.W. Holmes Materials Characterization, 35 (1995), 4, 199-206 |

| 736 | Surface roughness of ion implanted (100) silicon studied by atomic force microscopy E. Andre, D. Courboin, A. Grouillet Surface Science, 342 (1995), 1-3, l1111-l1115 |

| 737 | Surface roughness of oxidised copper films studied by atomic force microscopy and spectroscopic light scattering C.-G. Ribbing, J. Isidorsson, T. Lindstrom, D. Ronnow Thin Solid Films, 325 (1998), 1-2, 92-98 |

| 938 | Surface roughness of thin layers - A comparison of XRR and SFM measurements O. Filies, O. Boling, K. Grewer, J. Lekki, M. Lekka, Z. Stachura, B. Cleff Applied Surface Science, 141 (1999), 3-4, 357-365 |

| 147 | The Characterisation of Solids by Adsorption and Immersion Techniques and by AFM/STM F. Stoeckli, T.A. Centeno, D. Hugi-Cleary Journal of the European Ceramic Society, 18 (1998), 9, 1177-1185 |

| 756 | The determination of the elastic modulus of microcantilever beams using atomic force microscopy B. T. Comella, M. R. Scanlon Journal of Materials Science (full set), 35 (2000), 3, 567-572 |

| 765 | The microstructure of thin films observed using atomic force microscopy K.L. Westra, D.J. Thomson Thin Solid Films, 257 (1995), 1, 15-21 |

| 948 | The nano-scratch tester (NST) as a new tool for assessing the strength of ultrathin hard coatings and the mar resistance of polymer films R. Consiglio, N.X. Randall, B. Bellaton, J. von Stebut Thin Solid Films, 332 (1998), 1-2, 151-156 |

| 777 | True atomic resolution imaging with noncontact atomic force microscopy Y. Sugawara, H. Ueyama, M. Ohta, S. Morita, T. Uchihashi, M. Suzuki, S. Mishima Applied Surface Science, 113-114 (1997), 364-370 |

| 956 | Using scanning force microscopy (SFM) to investigate various cleaning procedures of different transparent conducting oxide substrates F.D. Auret, H.L. Gaigher, C.M. Demanet, J.M. Nel, K.T. Hillie Applied Surface Science, 134 (1998), 1-4, 22-30 |

| 1208 | A Model for Friction in Atomic Force Microscopy S. Salapaka and M. Dahleh Proc. of American Control Conf., Chicago, Illinois, June 2000. pp. 2102-2107 |

| 432 | Atomic-scale friction on diamond(111) studied by ultra-high vacuum atomic force microscopy R.J.A. van den Oetelaar, C.F.J. Flipse Surface Science, 384 (1997), 1-3, L828-L835 |

| 1436 | Bases of Chemical Force Microscopy by Friction: Energetics and Dynamics of Wearless Friction between Organic Monolayers in Terms of Chemical and Physical Properties of Molecules M. Fujihira and T. Ohzono Jpn. J. Appl. Phys., 38 (1999) 3918-3931 |

| 1303 | Differential friction force spectroscopy of micropatterned organosilane self-assembled monolayers H. Sugimura, H. Shiroyama, O. Takai, N. Nakagiri Applied Physics A: Materials Science & Processing, 72 (2001), 8, S285-S289 |

| 1396 | Effect of temperature on friction observed between a Si3N4 tip and a dodecanethiol self-assembled monolayer on Au(111) Mitsuhiro Fujita and Masamichi Fujihira Ultramicroscopy, 91 (2002) 1-4, pp. 227-230 |

| 69 | Friction studies of hydrogel contact lenses using AFM: non-crosslinked polymers of low friction at the surface S.H. Kim, C. Marmo, G.A. Somorjai Biomaterials, 22 (2001), 24, 3285-3294 |

| 509 | Friction tracks on diamond surfaces imaged by atomic force microscopy W.J.P. Van Enckevort, M. Seal, M.S. Couto Diamond and Related Materials, 6 (1997), 8, 975-982 |

| 1304 | Frictional anisotropy and sectorization in poly(4-methyl-1-pentene) lamellar crystals studied by lateral force microscopy G.J. Vancso, R. Pearce Polymer, 39 (1998), 26, 6743-6746 |

| 510 | Fundamental measurements of the friction of clean and oxygen-covered VC(100) with ultrahigh vacuum atomic force microscopy: evidence for electronic contributions to interfacial friction P.B. Merrill, S.S. Perry Surface Science, 418 (1998), 1, 342-351 |

| 1309 | Lateral force microscopy and force modulation microscopy on SILAR-grown lead sulfide samples M. Grasserbauer, M. Leskela, G. Friedbacher, R. Resch, T. Kanniainen, L. Niinisto, S. Lindroos Applied Surface Science, 120 (1997), 1-2, 51-57 |

| 1310 | Lateral force microscopy investigations of the crystallization of SrBi2Ta2O9 thin films B.K. Ju, K.B. Lee Thin Solid Films, 334 (1998), 1-2, 65-70 |

| 1311 | Lateral force microscopy study of functionalized self-assembled monolayer surfaces Y. Kim, K.-S. Kim, M. Park, J. Jeong Thin Solid Films, 341 (1999), 1-2, 91-93 |

| 1313 | Lubricious zinc oxide films grown by pulsed laser deposition: Lateral force microscopy of wear surfaces S. V. Prasad, J. J. Nainaparampil, J. S. Zabinski Journal of Materials Science Letters, 19 (2000), 22, 1979-1981 |

| 601 | Micro/nanotribology of ultra-thin hard amorphous carbon coatings using atomic force/friction force microscopy B. Bhushan, S. Sundararajan Wear, 225-229 (1999), 678-689 |

| 296 | Microfriction and macrofriction of metal containing amorphous hydrocarbon hard coatings determined by AFM and pin-on-disk tests Kirsten I. Schiffmann Tribology Letters, 5 (1998), 1, 109-116 |

| 1315 | Modelling of the scan process in lateral force microscopy H. Holscher, R. Wiesendanger, U.D. Schwarz Surface Science, 375 (1997), 2-3, 395-402 |

| 1318 | Normal and lateral force investigation using magnetically activated force sensors S.P. Jarvis, H. Yamada, K. Kobayashi, A. Toda, H. Tokumoto Applied Surface Science, 157 (2000), 4, 314-319 |

| 898 | Role of the force of friction on curved surfaces in scanning force microscopy J.P. Aime, Z. Elkaakour, S. Gauthier, D. Michel, T. Bouhacina, J. Curely Surface Science, 329 (1995), 1-2, 149-156 |

| 913 | Scanning force microscopy of poly(ethylene terephthalate) surfaces: comparison of SEM with SFM topographical, lateral force and force modulation data J.S.G. Ling, G.J. Leggett Polymer, 38 (1997), 11, 2617-2625 |

| 931 | Study of mixed Langmuir-Blodgett films of hydrocarbon and fluorocarbon amphiphilic compounds by scanning surface potential microscopy and friction force microscopy K. Yagi, M. Fujihira Applied Surface Science, 157 (2000), 4, 405-411 |

| 236 | Study of the influence of adsorbed water on AFM friction measurements on molybdenum trioxide thin films W. Gulbinski, D. Pailharey, T. Suszko, Y. Mathey Surface Science, 475 (2001), 1-3, 149-158 |

| 1319 | Study on surface structure of amorphous polymer blends on the basis of lateral force microscopy W.-K. Lee Polymer, 40 (1999), 20, 5631-5636 |

| 732 | Surface observation of Langmuir-Blodgett films of polyamic acid alkylamine salts and polyimide by atomic force microscopy and friction force microscopy S. Yokoyama, M. Kakimoto, Y. Imai Synthetic Metals, 81 (1996), 2-3, 265-270 |

| 294 | The dependence of friction anisotropies on the molecular organisation of LB films as observed by AFM D. Gourdon, N.A. Burnham, A. Kulik, E. Dupas, F. Oulevey, G. Gremaud, D. Stamou, M. Liley, Z. Dienes, H. Vogel, C. Duschl Tribology Letters, 3, 4, 317-324 |

| 1321 | The influence of pH on friction between oxide surfaces in electrolytes, studied with lateral force microscopy: application as a nanochemical imaging technique G. Hahner, A. Marti, N.D. Spencer Tribology Letters, 3, 4, 359-365 |

| 947 | The mechanism of PTFE and PE friction deposition: a combined scanning electron and scanning force microscopy study on highly oriented polymeric sliders H. Schonherr, G.J. Vancso Polymer, 39 (1998), 23, 5705-5709 |

| 769 | Theoretical analysis of atomic-scale friction in frictional-force microscopy N. Sasaki, M. Tsukada, S. Fujisawa, Y. Sugawara, S. Morita Tribology Letters, 4 (1998), 2, 125-128 |

| 771 | Theoretical simulation of atomic-scale friction in atomic force microscopy N. Sasaki, K. Kobayashi, M. Tsukada Surface Science, 357-358 (1996), 92-95 |

| 1434 | Velocity Dependence and Limitations of Friction Force Microscopy of Mica and Graphite Yasuo Hoshi, Takayoshi Kawagishi and Hideki Kawakatsu Jpn. J. Appl. Phys., 39 (2000) 3804-3807 |

| 1201 | Nanomechanical characterizations of metals and thin films M. Goken, M. Kempf, M. Bordenet and H. Vehoff Surface and Interface Analysis, 27 (1999), 302-306 |

| 1202 | Quantitative Microstructural Characterisation by Atomic Force Microscopy and Electron Microscopy - A Comparative Study on the Superalloy Waspaloy K. Durst and M. Goken Pract. Metallography, 38 (2001), 4, 197-216 |

| 1208 | A Model for Friction in Atomic Force Microscopy S. Salapaka and M. Dahleh Proc. of American Control Conf., Chicago, Illinois, June (2000) pp. 2102-2107 |

| 1217 | Alternative method for the activation and measurement of lateral forces using magnetically controlled atomic force microscopy S. P. Jarvis, H. Tokumoto, H. Yamada, K. Kobayashi, A. Toda Appl. Phys. Lett. 75 (1999) 24, pp. 3883-3885 |

| 1223 | Nanohardness measurements for studying local mechanical properties of metals M. Kempf, M. Goken, H. Vehoff Applied Physics A: Materials Science & Processing, 66 (1998) S843-S846 |

| 1284 | Friction experiments on the nanometre scale E Gnecco, R Bennewitz, T Gyalog and E Meyer J. Phys.: Condens. Matter 13 (2001) 31, R619-R64 |

| 1285 | Nanomechanics from atomic resolution to molecular recognition based on atomic force microscopy technology H. P. Lang, M. Hegner, E. Meyer and Ch. Gerber Nanotechnology 13 (2002) 5, R29-R36 |

| 1298 | Development of a continuous microscratch technique in an atomic force microscope and its application to study scratch resistance of ultrathin hard amorphous carbon coatings Sriram Sundararajan, Bharat Bhushan J. Mater. Res. 16 (2001) 2, 437-445 |

| 1659 | Application of lateral force imaging to enhance topographic features of polypropylene film and photo-cured polymers H.-Y. Nie, M.J. Walzak, N.S. McIntyre, and A.M. EL-Sherik Applied Surface Science, 144-145 (1999), pp.633-637 |

| 1666 | Experimental analysis of the influence of topography on the adhesion force as measured by an AFM A. Mendez Vilas, M. J. Nuevo, M. L. Gonzalez Martin, L. Labajos-Broncano Journal of Adhesion Science and Technology 16 (2002) 13, pp. 1737-1748 |

| 1686 | Measurement of Solution Viscosity by Atomic Force Microscopy Ahmed, N., Nino, D.F. and Moy, V.T. Rev. Sci. Instrum., 72 (2001) 6, pp. 2731-2734 |

| 2575 | Quantitative imaging of nanoscale mechanical properties using hybrid nanoindentation and force modulation S. A. Syed Asif, K. J. Wahl, R. J. Colton, O. L. Warren J. Appl. Phys., 90 (2001) 3, 1192-1200 |

| 2586 | Friction coefficient measurements by LFM on DLC films as function of sputtering deposition parameters L.V. Santos, V.J. Trava-Airoldi, E.J. Corat, K. Iha, M. Massi, R. Prioli, R. Landers Diamond and Related Materials, 11 (2002) 3-6, 1135-1138 |

| 2623 | A Novel approach for the investigation of mesoscopic contact mechanics R.Buzio, F.Buatier de Mongeot, C.Boragno, U.Valbusa Thin Solid Films, 428 (2003) 111-114 |

| 2624 | The contact mechanics of fractal surfaces R.Buzio, C.Boragno, F.Biscarini, F.Buatier de Mongeot & U.Valbusa Nature Materials, 2 (2003) 4, 233-236 |

| 2802 | Micromechanical Properties of Elastic Polymeric Materials As Probed by Scanning Force Microscopy S. A. Chizhik, Z. Huang, V. V. Gorbunov, N. K. Myshkin, and V. V. Tsukruk Langmuir, 14 (1998) 2606-2609 |

| 2803 | Nanomechanical Analysis of Polymer Surfaces V.V. Tsukruk and V.V. Gorbunov Probe microscopy, 2 (2002) 3-4, 241-247 |