Lift Mode

Stability in tapping mode and high sensitivity to magnetic forcesCo-Cr coated AFM probes with medium force constant

HQ:NSC18/Co-Cr/Al BS

The principles of digital magnetic recording have not changed since their inception. Information on digital magnetic media is stored in terms of bits - microscopic areas having or not having a local magnetic moment, thus expressing either a "high" or "low" level of digital signal.

The progress in hard disk engineering has been followed by ongoing reduction in the size of all the materials involved in the process of magnetic recording. Currently, the thickness of each magnetic sub-layer and protective carbon coating amounts to merely several nanometers, while the head hovers over the disk surface at heights less than 50nm. These small feature sizes require very accurate production of surfaces and careful protection from contamination. Height and magnetic images of a hard disk surface are shown in Fig. 1.

| Fig. 1. Topography and MFM images of a hard disk. Scan size 5µm. | |

|

|

| (a) Topography AFM image of a hard disk. | (b) MFM image of recorded bits. |

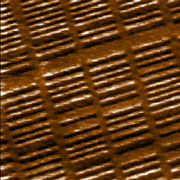

Similar images of a 3.5'' ZIP disk surface are shown in Fig. 2. Scan size is 50µm.

| Fig. 2. Topography and MFM images of the 3.5'' ZIP disk surface. Scan size 50µm. | |

|

|

| (a) Topography AFM image. | (b) MFM image of recorded bits. |

The AFM technique used for the characterization of both hard disks and read/write heads is known as Magnetic Force Microscopy (MFM). This is a two-pass mode, where surface topography is measured in tapping mode during the first pass and magnetic forces are mapped on the second pass with respect to the topography data.

AFM cantilevers with a magnetic Co-Cr coating should be used for MFM research. The force constant and resonance frequency of AFM cantilever should be chosen to provide stability in tapping mode as well as high sensitivity to weak magnetic forces during the second pass.

Lift Mode

Stability in tapping mode and high sensitivity to magnetic forcesCo-Cr coated AFM probes with medium force constant

HQ:NSC18/Co-Cr/Al BS