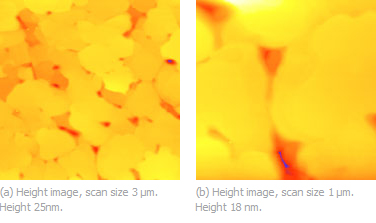

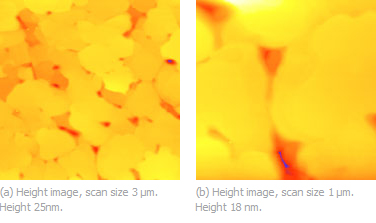

The characterization of metals and metallic compounds with AFM is a large and growing area. Noble metals (Pd, Ag, Pt, Au) in different forms have been studied not only because of their importance as catalysts and materials for sensors, but also due to their use as substrates for other materials. The most common substrate for organic layers is Au (111), which exhibits atomically-flat terraces as shown in Figures 1a-b. By varying the preparation conditions Au samples can be prepared as shots or coatings with crystalline domains of different lateral dimensions, their terraces reaching several microns in size. These surfaces are very convenient for the deposition of other materials, and a large number of STM and AFM studies have been performed on various thiols, which strongly bond (-Au-S-) to Au (111) surface.

| Figures 1a-b. Topography images of Au (111) sample showing multiple terraces with atomically-smooth surfaces. Height scale from blue to yellow. |

|

In general, AFM applications with metals can be split into three categories depending on the dimensional scale of interest and the characterization needs.

1. Visualization of crystalline lattices, surface reconstruction patterns, nanoparticles, nanowires and such processes as atomic and molecular diffusion and aggregation should be conducted with sharp AFM probes. The same is true for studies of sub-micron roughness and grain morphologies. To avoid damage of the AFM tip apex the use of these AFM probes in studies of most metal surfaces should be extremely careful (gentle engagement, low-force scanning).

2. Studies of large-scale morphology of metal surfaces, which is common for AFM applications in metallurgy (visualization of domains, surface defects, technological marks, etc) can be conducted with AFM probes which have an apex in the range of 40-50nm. The use of these AFM probes is beneficial when extreme resolution (say below 10nm) is not important. The suggested AFM probes have the advantage of being highly durable, therefore an operator can be less cautious with tip-sample force control. AFM probes with hard coatings can also be used.

3. Studies of metal surfaces with electric and magnetic AFM-methods require the use of AFM probes with conductive (Pt) and magnetic (Co-Cr) coatings. The spectrum of these AFM probes, which include AFM cantilevers of different stiffness and even different shapes, is growing with the expansion of electric modes to broadband and multi-frequency domains.

Generally, metals have sufficient mechanical stiffness to be examined in tapping mode with standard AFM probes with stiffness of ~40N/m. The use of softer AFM probes might be necessary for samples with increasing layer thickness if the topmost topography is of primary interest. Stiffer AFM probes might be necessary when imaging heterogeneities and to reveal sub-surface morphology that requires AFM tip penetration into the material.